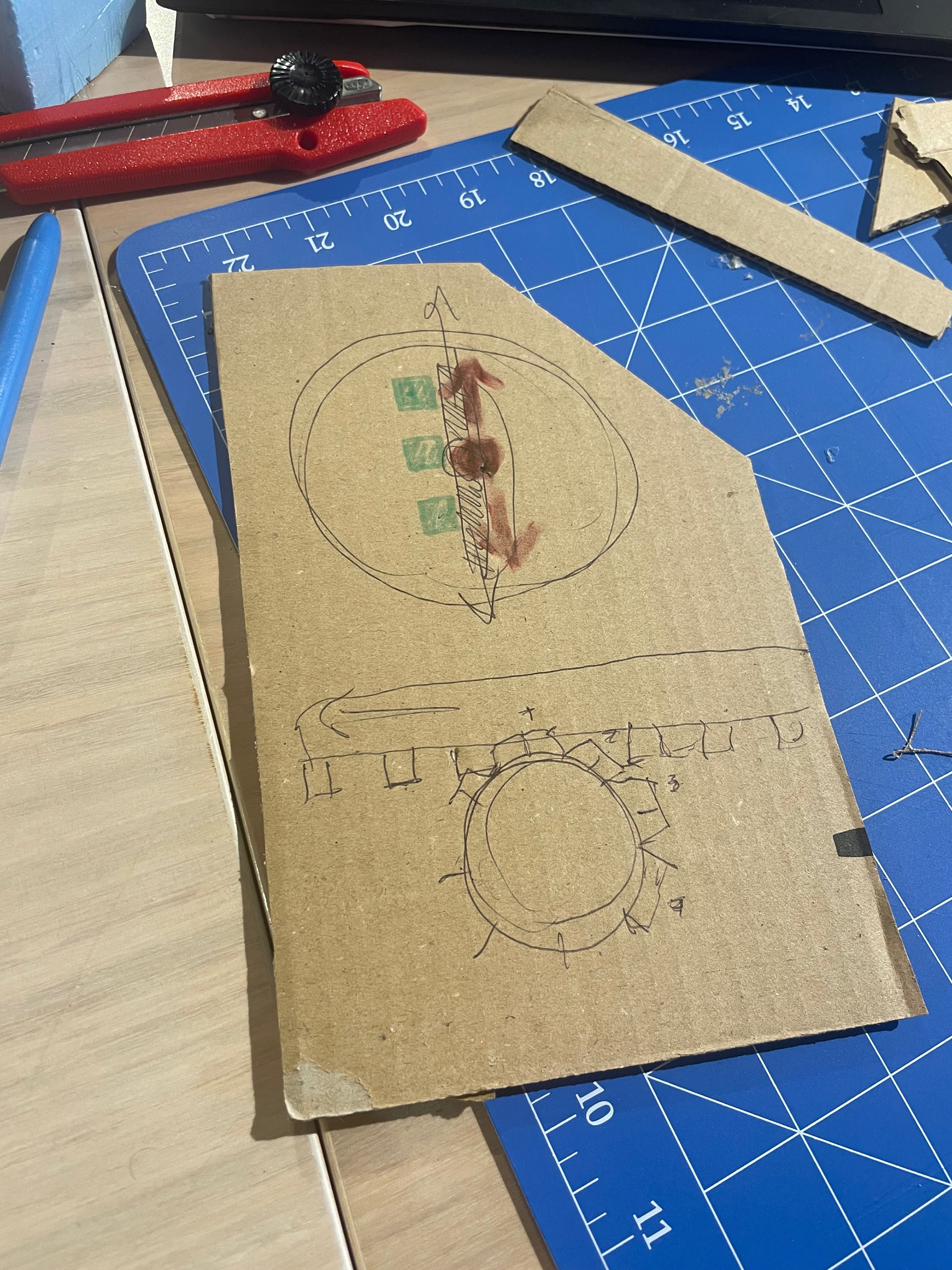

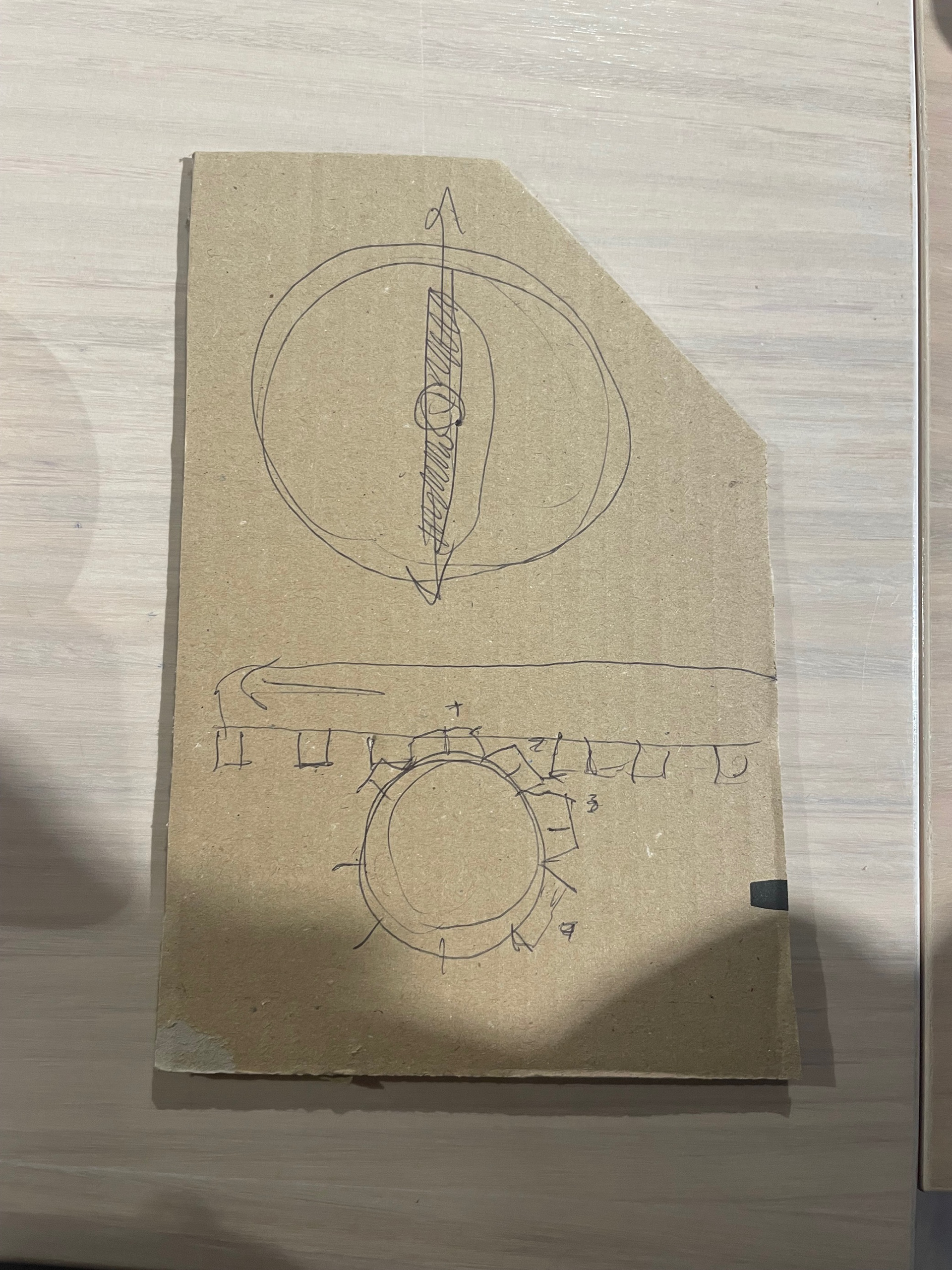

When looking at how to create a personal-use dough sheeter, the first iterations of prototyping began with basic materials like cardboard, tape, popsicle sticks and markers. The initial shape and idea was created through large pieces of cardboard, with other details penned on the surface to indicate case interface and internal structures and machinery. From this prototype, several things were realised;

– the next prototypes needed to have a minimum dimensions to be able to still be feasible as a personal kitchen item and to house the intended internal machinery,

– fail-safes and adaptive measures would need to be better explored to ensure that the final design met with the pain points and core needs of the user and,

– the user-interface of the product would need to also be explored in more detail

Looking at these three areas, further design decisions could be applied for understanding, exploration and possibly testing. This prototype was completed within a group environment, with a focus on understanding the spatial awareness of the final design and it's user-interface and operation options.

Universal Design in the Kitchen, Domestic Dough Sheeter Prototype. Created with cardboard, masking tape, popsticks and paper. Above veiw.

Universal Design in the Kitchen, Domestic Dough Sheeter User-Interface Prototype. Created with cardboard, masking tape, popsticks and paper.

Universal Design in the Kitchen, Domestic Dough Sheeter User-Interface Prototype. Created with cardboard, masking tape, popsticks and paper.

Universal Design in the Kitchen, Domestic Dough Sheeter Internal Interface Prototype. Created with cardboard, masking tape, popsticks and paper.

Universal Design in the Kitchen, Domestic Dough Sheeter Prototype. Created with cardboard, masking tape, popsticks and paper. Three-quarter side view, back.

Universal Design in the Kitchen, Domestic Dough Sheeter Prototype. Created with cardboard, masking tape, popsticks and paper. Back view.

Universal Design in the Kitchen, Domestic Dough Sheeter Prototype. Created with cardboard, masking tape, popsticks and paper. Three-quarter side view, front.

Universal Design in the Kitchen, Domestic Dough Sheeter Prototype. Created with cardboard, masking tape, popsticks and paper. Front view.

This prototyping session was completed with very little preparation or understanding of what the product could look like and allowed an understanding that prototyping ideas may have been better engaged with if there had been a more detailed plan prior. Using the basic materials did accommodate for the lack of planning, as they allowed for the prototype to be adapted and changed as the session continued. Within the group, individual components and features were focused on; with a UX background, the user-interface options were important to focus on, which was supported by collaboration with those in the team with a background in OT. This prototype was completely mainly in equal contributions, with features being discussed as they were being created and then modified.

Within the team, several different ideas came up and this prototype went on to be presented for further feedback from colleagues who pointed out similar opportunities as mentioned earlier, but who also were more specific to areas that had not been thought of before; what kind of cleaning functions would it have? How easy would it be to move, depending on the materials? These features may have been touched on briefly, but not all of the time so it was imperative that the starting prototype received feedback from outside of the team. Future prototyping sessions for this project would need to be prepared for to ensure that time and materials are better equipped and utilised for the overall design iterations.